- Cable wire Coiling Binding

- Tape winding machine

- Semi-auto strip twist brush

- Wire cutting stripping machine

- Semi-auto crimping machine

- Stripper crimper Blades

- Terminal Tensile Tester

- Cut-off machine

- Cable labeling machine

- Strapping banding tool

- Terminals/connector/Plugs

- Automated Tape Dispenser

- Automatic Crimp Machine

- Terminal Crimping tools

- Auto Wire feeder

- Automatic soldering machine

- Nylon Cable Tie Machine

- Injection molding machine

- Brazing welding machine

- Screw fastening machine

- Power cord crimping machine

- Wire harness tester

- Glue Dispensing Robot

- Wiring harness Packing materials

Copper belt crimping copper wire joint splicing machine cable terminal

Model No:

copper belt crimping, copper wire joint splicing machine cables terminal making machine ModelTDJ-1.8TTDJ-3.0TTDJ-4.0T

Power supply voltageAC220V 50/60HZ

Pressing force1800kg3000KG4000KG

Motor power0.55KW1.0KW1.5KW

Feed length22mm32mm42mm

Copper strip width2/4/6mm6/8/10mm6/8/10mm

Size310x450x480mm330x600x630mm430x700x730mm

Weight45kg110kg130kg

- Inquiry now

copper belt crimping, copper wire joint splicing machine cables terminal making machine

Features:

Adopting high-tech frequency conversion technology; electronic precise positioning; when the motor is crimped, the noise is smaller than the traditional copper belt machine, and it saves electricity; the mold adjustment is more convenient and quick; avoid the common failures of the traditional terminal machine clutch, electromagnet, etc.!

1. This machine is specially designed for wires that need to be processed by fusion, with fast speed and good quality;

2. The wire is connected by the crimping method, replacing the traditional soldering method, without the shortcomings of cold welding, air welding, and air pollution. It is the easiest and most effective way to pass various safety standard tests;

3. The use of special continuous copper tape terminals (patents are on file, please do not counterfeit) materials are cut, formed, pressed, and completed at one time, quickly and without waste, saving costs;

4. The copper strip terminal has been treated with special textures and has strong tensile strength after being folded, and the quality is stable; 5. It is suitable for earphone cables, data cables, electronic cable docking, resistance/lamp docking, automobile wiring harness, etc., humanized design, without training, can be operated at any time.

|

Model |

TDJ-1.8T |

TDJ-3.0T |

TDJ-4.0T |

|

|

Power supply voltage |

AC220V 50/60HZ |

|||

|

Pressing force |

1800kg |

3000KG |

4000KG |

|

|

Motor power |

0.55KW |

1.0KW |

1.5KW |

|

|

Feed length |

22mm |

32mm |

42mm |

|

|

Copper strip width |

2/4/6mm |

6/8/10mm |

6/8/10mm |

|

|

Size |

310x450x480mm |

330x600x630mm |

430x700x730mm |

|

|

Weight |

45kg |

110kg |

130kg |

|

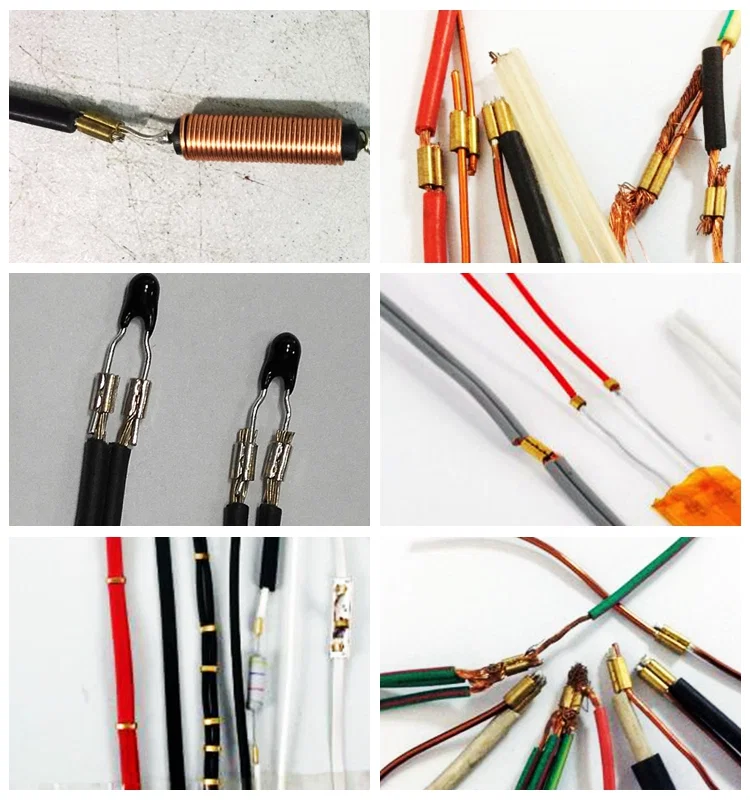

Processing result

- Categories

- Cable wire Coiling Binding

- Tape winding machine

- Semi-auto strip twist brush

- Wire cutting stripping machine

- Semi-auto crimping machine

- Contact Us

sales@cablecutting.net

sales@cablecutting.net kevin201166

kevin201166 +86-18965153335

+86-18965153335

- Copyright @ 2003-2023 XIAMEN JINGWEI TECHNOLOGY CO., LTD.

- E-mail sales@cablecutting.net npsales@126.com

- Contact: Mr. Kevin, Ms. Donna

- Tel:+86-0592-8628902 Mobile:+86-18965153335 Skype: kevin201166 Fax:+86-0592-6065010